News

- Air pump use and maintenanceZYB sliding vane vacuum pressure compound air pump has become an indispensable auxiliary machine for printing and binding due to its small size, compact structure and automatic lubrication. 1 Common faults and elimination of air pump 1) The sound is normal, but the vacuum pressure does not reach the nameplate label. Solution: ① The asbestos pad at the base of the air inlet and outlet positioning package is not tight or broken, and the asbestos pad should be replaced; ② The control valve is damaged, and it cannot be adjusted, and it should be replaced immediately; ③ The rubber seal ring of the filter at the side suction is not The cover nut is not tightened tightly. 2) Abnormal sound. Solution: ① Insufficient oil quantity, poor lubrication, oil should be added to the oil mark height; ② The oil pump is damaged, no lubricating oil, replace the oil pump; ③ Click sound, the shaft at both ends of the air pump rotor is damaged, replace immediately; ④ The fan blade is aging or Interrupted and replaced after removing the fault; ⑤ The lack of oil in the cylinder makes the friction between the large steel sheet and the missing body intensify. Replace the damaged parts after repairing the oil circuit. 3) Oil leakage. Solution: ① The pipeline problem, the tubing joint is not tight or the tubing is damaged, one by one; ② The sealing problem, the main reason for the failure is that the pump shaft of the vacuum pump and the seal ring of the oil seal device are worn, and the seal ring should be replaced immediately. 4) No gas. Solution: ①The shaft of the coupling of the air pump has been broken, the air pump is not working, the shaft should be replaced; ②The motor does not run, the circuit is faulty, the circuit is repaired, the fault is eliminated and the motor runs. 5) The air pump sucks air. The vacuum degree of blowing is reduced. The main reasons are: ① The oil in the vacuum pump is insufficient; ② There are many impurities in the air pump, and the air pump is blocked; ③ The wear of the sealing parts of the air pump causes oil leakage. Air leakage; ④ The air filter in the air pump is blocked; ⑤ The air pump regulating valve is improperly adjusted. Remedy: ①Add new vacuum oil to the centerline of the cursor; ②Replace the new vacuum oil; ③Use new seals; ④Use gasoline to clean the filter. Air filter; ⑤ Adjust the regulating valve of the air pump correctly, increase the pressure in a clockwise direction, and vice versa. 6) Check items that should be paid attention to during the use of the air pump: ① Whether the auxiliary air inlet of the regulating valve is blocked; ② The auxiliary air inlet is blocked to cause little blowing; ③ Whether the filter is blocked, and whether the relevant rubber pad is installed Normal; ④The diameter of the air inlet and outlet can't be too small, the normal side is the standard. [next] 2 Maintenance of ZYBW vacuum pressure compound air pump 1) The ZYBW type vacuum pressure compound air pump consists of a pump body. Filtration system. Composed of air cooling system. Should be placed in clean. There should be no obstacles in the ventilating place and the cooling air inlet and outlet of the pump, so as not to affect the cooling effect. The distance between the cooling air inlet and the wall and other obstacles is more than 30cm, and it is not allowed to cover the air pump and the air outlet with debris, so as not to affect Heat dissipation. 2) Suction pipe connector. The exhaust pipe joint shall not be arbitrarily reduced in diameter, and the length of the air pipe used should be as short as 3m. 3) The rotation direction of the air pump is consistent with the steering nameplate, and reverse rotation is strictly prohibited. Each time you rewire the installation, pay attention to the correct direction of rotation to prevent damage to the air pump due to reverse rotation. 4) The suction vacuum and discharge pressure have been limited to the rated value at the factory, and the vacuum and pressure can be adjusted by turning the knob of the valve. Non-professionals should not adjust the screw in the middle of the copper sleeve in the valve to prevent the increase of the working load of the pump body, otherwise it will damage the adjustment valve lightly and affect the service life of the air pump. 5) In accordance with the provisions of the grease use label, replenish the two oil nozzles of the rotor bearing position with lubricant. 6) Periodically check and replace the graphite slide. After the air pump has operated for 5000 hours in total, remove the air inlet hood, loosen the hexagon socket screws on the end cover, remove the end cover equipped with bearing seat parts, and remove the graphite slide. When the width of the graphite slide is less than 3/4 to 5/8 of the rotor groove depth, it should be replaced. If the amount of blowing or inhaling suddenly decreases, the graphite slide may be damaged. In this case, the graphite slide needs to be replaced to restore the air supply. 7) Regularly clean the air filter to prevent paper dust from clogging the air inlet and make the air pressure supply of the air pump abnormal. 8) The elastic ring of the coupling is checked every six months. If the elastic ring is worn out, it should be replaced in time. When re-installing, ensure that there is a 2 ~ 3cm gap between the two couplings. [next] 3 Daily maintenance of air pump 1? Change the vacuum oil regularly. After the air pump has been working for a period of time, there will be traces of metal iron filings in the oil. Paper gray. Fiber debris will wear the cylinder under the working state of the air pump, so the vacuum oil of the air pump should be replaced in time. In addition, special vacuum oil should be used instead of ordinary motor oil. 2? Ensure that the air pump cooling pipe is clean The air pump has more than a dozen cast aluminum tube cooling pipes, often called heat pipes, and their role is to cool the hot air in the pump. Long years of work will cause a thick layer of grease and dust to accumulate on the cooling tube, which must be cleaned in time, otherwise it will affect the cooling effect, resulting in burnout of bearings and sliding blades. 3? Ensure that the heat dissipation of the air pump is good. The heat dissipation of the air pump is achieved by the convection of hot and cold air, so the air pump should be placed in a large space. Easily ventilated place. When the air pump is operated in a high temperature state for a long time, the temperature of the pump body will be very high, and the air pump is easily burned out. At this time, the fan should be used to help the heat dissipation of the air pump, and its effect is relatively ideal. 4? Clean the filter regularly The role of the filter is to filter the air. When the suction filter sucks, avoid sucking the paper dust into the air pump; when the blowing filter blows, avoid blowing oil mist on the surface of the paper; in addition, there are four oil filters on the base of the air pump, and their function is to remove the oil mist. Prevent oil mist from being blown out. Therefore, it is necessary to regularly check whether the filter is damaged, and clean or replace it in time.

2022 06/30

- Air compressor noise reduction technology, air compressor noise control scheme, reduce air compressor noiseAir compressor noise control technology and air compressor noise reduction scheme, Shenzhen Quelte Sound and Noise Reduction Engineering Technology Co., Ltd. specializes in noise control of mechanical equipment and noise reduction. Air compressor is a power equipment widely used in industrial production , but the air compressor is very noisy when operating , usually in the range of 90~110Db(A), and it has low frequency characteristics, which seriously affects the surrounding environment, especially at night. It reaches hundreds of meters . Therefore, air compressor noise is a problem of industrial noise control are often encountered. Air compressors can be divided into two types, volumetric and vane, according to their working principle. Air compressors are a comprehensive source of noise. The noise of the air compressor is mainly composed of aerodynamic noise radiated from the inlet and outlet ports, mechanical noise generated by mechanical moving parts, and vibration of the driving motor . Air compressor noise control method First, the air inlet is installed with a muffler Generally, the nearest port can be led to the outside, and then a muffler can be added. Since the intake noise has a low frequency characteristic, an impedance composite muffler, a micro-perforated composite muffler, a venturi muffler, and the like are generally installed. Second , air compressor shock absorption The air compressor has a large vibration, and it is usually necessary to perform shock absorption treatment on the base. The shock absorption design and shock absorption product selection are performed according to the weight and vibration frequency of the air compressor. The exhaust of the air compressor to the pipeline of the gas storage tank generates vibration and radiates noise due to the pressure pulse of the exhaust gas. It not only causes fatigue damage to pipes and supports, but also affects the surrounding environment. To this end, the pipeline needs to be protected against vibration and noise. Commonly used exhaust pipe is equipped with a cut-off orifice plate and avoiding the length of the resonance pipe. Third , the air compressor installed sound insulation cover In the case of high environmental noise requirements, for the noise of the air compressor, only installing the muffler at the air inlet often fails to meet the noise reduction requirements, and must also deal with the noise radiated by the casing and mechanical components, and install the whole unit. The acoustic mask is an effective measure to control this noise. The sound enclosure should be designed to ensure its airtightness for good sound insulation. In order to facilitate inspection and disassembly, the sound enclosure can be designed to be detachable, and the inspection door and observation window are reserved. At the same time, the heat dissipation problem of the unit should be considered, and the muffler should be installed at the inlet and outlet. Fourth, the noise control of the gas tank The air compressor continuously delivers the compressed gas to the gas storage tank, and the compressed air in the tank generates excitation vibration under the action of the air flow pulsation, which is accompanied by strong noise and simultaneously excites the vibration radiation noise of the casing. In addition to the sound insulation method, the noise can also be used to suspend the sound absorbing body in the gas storage tank, and the sound absorbing effect of the sound absorbing body is used to hinder the formation of standing waves in the tank, thereby achieving the purpose of sound absorption and noise reduction. V. Comprehensive treatment of noise in air compressor stations Many companies, usually with multiple compressors for production needs, have built air compressor stations. The noise of the compressor is very large. If a muffler is installed on the air inlet of each air compressor, not only the workload is large, but also the investment is large. Therefore, noise reduction measures such as sound absorption, sound insulation, and sound insulation can be taken in the station. From the perspective of the effect and investment of noise control, such as the noise control measures in the air compressor station process design and civil construction, the investment can be reduced and better noise reduction effect can be obtained. Shenzhen Quilter noise reduction Engineering Co., Ltd. is specialized in air compressor air compressor noise control and noise reduction, product development, design, construction and acoustics solutions dedicated compressed air as one of the engineering and technology companies, professional machine noise and vibration comprehensive management and research, to address air compressor noise, air compressor equipment for different types of noise control and air compressor station house, to provide users with on-site noise surveys, analysis, provides system solutions and air compressor noise Construction services. Main business: Civil use: Noise reduction in residential quarters and residential houses , noise control in pump house, noise control in air conditioning systems, noise control in generator rooms, noise control in power distribution rooms, noise control in transformer rooms, noise control between machinery and equipment , hotel, office and office space Acoustic noise reduction , acoustic design and construction of functional buildings such as conference centers, concert halls, stadiums, and theaters. Industry: noise control of mechanical equipment, noise reduction, noise reduction , noise reduction of medical equipment, noise reduction, noise reduction of workshops, sound insulation and noise reduction, noise reduction of fan room, noise reduction of air compressor room , equipment production line noise reduction and other production equipment noise and environmental noise control in the plant area, sound insulation, shock absorption, noise reduction and other comprehensive noise control projects. All kinds of sound insulation doors, sound insulation windows, sound insulation rooms, sound insulation covers, sound insulation screens and other sound insulation projects.

2022 05/09

- Spring Festival expects 42 million passengers to fly by airDuring the Spring Festival of 2014, the passenger traffic of China`s civil aviation is expected to reach 42 million passengers, an increase of 10% over 2013. At the National Civil Aviation Working Conference held here on the 24th, Xia Xinghua, the deputy director of the Civil Aviation Administration, stated that all CAAC units must clearly define their responsibilities, implement plans, reduce flight delays, and make efforts to complete the flight schedule. Xia Xinghua said that in order to meet the flight operations during the Spring Festival, the Civil Aviation Administration promptly adjusted its policies and reduced the entry threshold for overtime work on domestic routes. The CAAC and regional administrations actively accepted applications for overtime charter flights by domestic and international airlines on Hong Kong, Macau and Taiwan routes, simplifying the procedures for handling and meeting market demands. At present, the Civil Aviation Administration has accepted 428 overtime classes and 802 international overtime classes during the Spring Festival. It is expected that the number of domestic overtime will reach 12,000 round-trip flights this year. Xia Xinghua analyzed that during the Spring Festival, passengers increased, and the number of flights increased. Most of them were concentrated on busy routes. The weather factors were more complicated, and extreme weather such as ice, snow, and fog often occurred, which had a greater impact on the normal operation of flights and increased the difficulty of protection. He stressed that all airlines should take effective measures to reduce flight delays caused by the company`s own reasons; the air traffic control department should give full play to the role of the operation coordination mechanism and implement various measures to [block congestion and maintain smoothness" and strengthen cooperation with airlines. Coordination between airports and airports; airports should ensure smooth and orderly ground operations and avoid collisions. In particular, in the event of large-scale flight delays, it is necessary to strengthen close cooperation with local governments and highways, railways and other units to ensure smooth travel. (Reporter Lin Hongmei, Fan Wei) document.getElementById("bdshell_js").src = "http://bdimg.share.baidu.com/static/js/shell_v2.js?cdnversion=" + new Date().getHours();

2022 04/08

- The principle and characteristics of screw air compressor and ordinary air compressorThe main compressor is divided into piston, screw and centrifugal. Pistons are rarely used now, old machines. Use a screw with a small amount of gas and centrifuge with a large amount of gas. Structure and working principle 1. Piston oil-free lubricated air compressor Piston oil-free lubricated air compressor is composed of compressor main unit, cooling system, regulating system, lubrication system, safety valve, motor and control equipment. The compressor and the motor are fastened to the base with bolts, and the base is fixed to the foundation with anchor bolts. When working, the motor directly drives the crankshaft through the coupling, drives the connecting rod, the crosshead and the piston rod, and makes the piston reciprocate in the compressor cylinder to complete the suction, compression, and discharge processes. The machine is a double-acting compressor, that is, the piston moves upwards and downwards, all have air suction, compression and discharge. 2. Screw air compressor Screw air compressor is composed of screw head, motor, oil and gas separation barrel, cooling system, air conditioning system, lubrication system, safety valve and control system. The whole machine is installed in a box, which is self-contained and can be placed directly on the flat concrete floor without fixing it with anchor bolts. The screw head is a kind of dual-shaft displacement rotary compressor head. A pair of high-precision main (male) and auxiliary (female) rotors are installed horizontally and parallel inside the casing. The main (male) rotor has 5 teeth and the auxiliary (female) rotor has 6 teeth. The main rotor has a large diameter and the auxiliary rotor has a small diameter. The teeth form a spiral shape, and the two mesh with each other. Both ends of the main and auxiliary rotors are respectively supported and positioned by bearings. During operation, the motor directly brings the main rotor through the coupling (or belt). Since the two rotors mesh with each other, the main rotor directly drives the auxiliary rotor to rotate together. The cooling liquid is directly sprayed into the rotor meshing part by the nozzle in the lower part of the compressor casing, and is mixed with the air to take away the heat generated by the compression to achieve the cooling effect. At the same time, a liquid film is formed to prevent direct metal-to-metal contact between the rotors and to close the gap between the rotors and the casing. The injected coolant can also reduce the noise generated by high-speed compression. The main components of the screw air compressor are the screw head and the oil-gas separation barrel. The screw head sucks air through the suction filter and the intake control valve, while oil is injected into the air compression chamber to cool and seal the head and lubricate the screw and bearings. The compression chamber generates compressed air. The compressed oil-gas mixture gas is discharged into the oil-gas separation barrel. Due to the mechanical centrifugal force and gravity, most of the oil is separated from the oil-gas mixture. Air passes through the oil and gas separation cylinder core made of boron silicate glass fiber, and almost all the oil mist is separated. The oil separated from the oil-gas separation cylinder core returns to the screw head through the oil return pipe. An oil filter is installed on the oil return pipe. After the oil return is filtered by the oil filter, the clean oil flows back into the screw head. When the oil is separated, the compressed air leaves the oil and gas cylinder through the minimum pressure control valve and enters the aftercooler. The after-cooler cools the compressed air and discharges it to the air storage tank for use by each air-consuming unit. The condensed water is concentrated in the air storage tank and discharged through an automatic drain or manually. Features 1. Piston oil-free lubricated air compressor The piston ring in the cylinder of the oil-free lubricated air compressor and the packing in the packing device are filled with self-lubricating polytetrafluoroethylene as the sealing element. Therefore, the cylinder and the packing device do not need to be lubricated with lubricating oil. Under normal circumstances, the compressed gas is basically pure and free of oil pollution, and there is no need to add an oil removal device. The shortcomings of this machine are that the motor power is too large, the exhaust pressure is not stable enough, the exhaust temperature is high, the noise is too large, the maintenance workload is large, and the maintenance cost is too high. 2. Screw air compressor The precise cooperation between the male and female rotors of the screw air compressor and the rotor and the casing of the body reduces the gas return leakage and improves the efficiency; only the inter-rotation of the rotors and the reciprocating movement of the cylinders reduce the source of vibration and noise. The unique lubrication method has the following advantages. With the pressure difference generated by itself, it continuously injects cooling fluid into the compression chamber and bearings, which simplifies the complex mechanical structure; the injection of cooling fluid can form a liquid film between the rotors, and the auxiliary rotor can be directly The main rotor is driven without the help of high-precision synchronous gears; the injected coolant can increase the effect of air tightness, reduce the noise caused by high-frequency compression, and also absorb a large amount of compression heat. Therefore, the single-stage compression ratio is even Up to 16 can also prevent the exhaust temperature from being too high, and there will be no friction between the rotor and the casing due to different thermal expansion coefficients. Therefore, the screw air compressor has the advantages of low vibration, no need to be anchored on the foundation, low motor power, low noise, high efficiency, stable exhaust pressure, and no wearing parts. The shortcoming of this machine is that the compressed air contains oil, and its oil content is 1 ~ 3 × 10-6. For the process with strict requirements on the oil content of compressed gas, an oil removal device needs to be added. The plant's compressed air system has added a two-stage oil removal device. Because the compressed air in the ADC process directly contacts the product ADC foaming agent, the quality of the air is more demanding, and the gas used in the ADC process has a three-stage oil removal device. See Table 1 for the comparison of compressor performance parameters. Major failure 1. Piston oil-free lubricated air compressor The piston ring and packing device of this machine do not need oil injection and lubrication. Under normal circumstances, the compressed gas is basically pure and does not contain oil, but because the oil scraping ring often scrapes the oil incompletely and the seal is not good, oil often runs on the packing device or even the piston ring, so that the compressed gas contains oil. In addition, the exhaust temperature is high, sometimes as high as 200 ℃; the cooler is clogged, so that the cooling effect is not good; the piston ring is stained with oil, and it is particularly easy to wear; the valve racket leaks; the cylinder liner wears etc. 2. Screw air compressor The screw air compressor has few failures, as long as it regularly maintains the oil and gas separator, air and oil filter, etc., it can ensure its normal operation. The maintenance of the two 10m3 screw machines used for maintenance is clogged sewage pipes and control panel failures. The host system has been operating normally for 2 years. Conclusion From the use effect, the screw air compressor has the unparalleled advantages of the piston air compressor, which not only reduces the labor intensity of the operator, but also does not need to be equipped with a maintenance worker, which greatly reduces the maintenance cost. On the other hand, when the piston machine is used, the exhaust pressure is occasionally too low, which causes the ionic membrane control system to alarm. After switching to the screw machine, the exhaust pressure is set at 0.58MPa, the pressure remains stable, and there has not been any exhaust. The pressure is too low to cause the alarm of the ion membrane control system, thus ensuring the safe production of the ion membrane system.

2022 03/12

- Instructions for use of micro vacuum pump, micro air pumpSupply of micro vacuum pumps | micro air pumps | micro gas sampling pumps | micro gas circulation pumps | micro air pumps | micro suction pumps | micro air pumps Pumping and pumping dual-purpose, high pressure, large flow-(PCF series) 1. Main features: high temperature resistance (0-100 ℃); both the pumping and exhaust ends can carry large loads (that is, large resistance), or even blockage; maximum output pressure: up to 1 kg (0.1MPa), maximum flow: 15L / Min; low power consumption (<20 watts), small size and extremely long life. 2. Oil-free, non-polluting working medium, maintenance-free, can run continuously for 24 hours, allowing the medium to be rich in water vapor and installed in any direction; 3. Application: It can be pumped up or used in the gas path system with large exhaust resistance; transfer gas, accelerate gas flow, pressurize, etc .; 4. Target: Customers in many fields such as scientific research, gas sampling, instrumentation, chemical analysis, healthcare, medicine and health, biological engineering, automatic control, environmental protection, water treatment, etc. 5. For more detailed parameters, please visit (Chengdu Xinweicheng Technology Co., Ltd.) website

2022 03/04

- Air compressor noise reduction technology, air compressor noise control scheme, reduce air compressor noiseAir compressor noise control technology and air compressor noise reduction scheme, Shenzhen Quelte Sound and Noise Reduction Engineering Technology Co., Ltd. specializes in noise control of mechanical equipment and noise reduction. Air compressor is a power equipment widely used in industrial production , but the air compressor is very noisy when operating , usually in the range of 90~110Db(A), and it has low frequency characteristics, which seriously affects the surrounding environment, especially at night. It reaches hundreds of meters . Therefore, air compressor noise is a problem of industrial noise control are often encountered. Air compressors can be divided into two types, volumetric and vane, according to their working principle. Air compressors are a comprehensive source of noise. The noise of the air compressor is mainly composed of aerodynamic noise radiated from the inlet and outlet ports, mechanical noise generated by mechanical moving parts, and vibration of the driving motor . Air compressor noise control method First, the air inlet is installed with a muffler Generally, the nearest port can be led to the outside, and then a muffler can be added. Since the intake noise has a low frequency characteristic, an impedance composite muffler, a micro-perforated composite muffler, a venturi muffler, and the like are generally installed. Second , air compressor shock absorption The air compressor has a large vibration, and it is usually necessary to perform shock absorption treatment on the base. The shock absorption design and shock absorption product selection are performed according to the weight and vibration frequency of the air compressor. The exhaust of the air compressor to the pipeline of the gas storage tank generates vibration and radiates noise due to the pressure pulse of the exhaust gas. It not only causes fatigue damage to pipes and supports, but also affects the surrounding environment. To this end, the pipeline needs to be protected against vibration and noise. Commonly used exhaust pipe is equipped with a cut-off orifice plate and avoiding the length of the resonance pipe. Third , the air compressor installed sound insulation cover In the case of high environmental noise requirements, for the noise of the air compressor, only installing the muffler at the air inlet often fails to meet the noise reduction requirements, and must also deal with the noise radiated by the casing and mechanical components, and install the whole unit. The acoustic mask is an effective measure to control this noise. The sound enclosure should be designed to ensure its airtightness for good sound insulation. In order to facilitate inspection and disassembly, the sound enclosure can be designed to be detachable, and the inspection door and observation window are reserved. At the same time, the heat dissipation problem of the unit should be considered, and the muffler should be installed at the inlet and outlet. Fourth, the noise control of the gas tank The air compressor continuously delivers the compressed gas to the gas storage tank, and the compressed air in the tank generates excitation vibration under the action of the air flow pulsation, which is accompanied by strong noise and simultaneously excites the vibration radiation noise of the casing. In addition to the sound insulation method, the noise can also be used to suspend the sound absorbing body in the gas storage tank, and the sound absorbing effect of the sound absorbing body is used to hinder the formation of standing waves in the tank, thereby achieving the purpose of sound absorption and noise reduction. V. Comprehensive treatment of noise in air compressor stations Many companies, usually with multiple compressors for production needs, have built air compressor stations. The noise of the compressor is very large. If a muffler is installed on the air inlet of each air compressor, not only the workload is large, but also the investment is large. Therefore, noise reduction measures such as sound absorption, sound insulation, and sound insulation can be taken in the station. From the perspective of the effect and investment of noise control, such as the noise control measures in the air compressor station process design and civil construction, the investment can be reduced and better noise reduction effect can be obtained. Shenzhen Quilter noise reduction Engineering Co., Ltd. is specialized in air compressor air compressor noise control and noise reduction, product development, design, construction and acoustics solutions dedicated compressed air as one of the engineering and technology companies, professional machine noise and vibration comprehensive management and research, to address air compressor noise, air compressor equipment for different types of noise control and air compressor station house, to provide users with on-site noise surveys, analysis, provides system solutions and air compressor noise Construction services. Main business: Civil use: Noise reduction in residential quarters and residential houses , noise control in pump house, noise control in air conditioning systems, noise control in generator rooms, noise control in power distribution rooms, noise control in transformer rooms, noise control between machinery and equipment , hotel, office and office space Acoustic noise reduction , acoustic design and construction of functional buildings such as conference centers, concert halls, stadiums, and theaters. Industry: noise control of mechanical equipment, noise reduction, noise reduction , noise reduction of medical equipment, noise reduction, noise reduction of workshops, sound insulation and noise reduction, noise reduction of fan room, noise reduction of air compressor room , equipment production line noise reduction and other production equipment noise and environmental noise control in the plant area, sound insulation, shock absorption, noise reduction and other comprehensive noise control projects. All kinds of sound insulation doors, sound insulation windows, sound insulation rooms, sound insulation covers, sound insulation screens and other sound insulation projects.

2022 02/23

- Analysis and Research of Air Spring Forming MachineThe LCW-0QJ air spring forming machine is mainly composed of a molding machine main machine, a lower pressing roller device, a radial shrinking tire forming machine head, a tailstock device, a whole base, a pneumatic pipe system and an electric control system. For easy installation and installation, set the integral base. The motor drives the spindle to rotate, and the forming head and the main shaft are coupled by a sleeve. The forming head is a radial contraction tire forming machine head, and the folding is realized by a pair of synchronous cylinder mechanisms. The control aspect adopts PLC automatic control and touch screen technology, which can perform manual and program control operations. It can make axial and self-rotating motion with respect to the forming drum, and utilizes the pressure of the air cylinder and the matching transmission device. When forming, the forming head is in the best state of the simple supported beam. In order to make the device flexible, reliable, safe and durable, the rear roller seat movement is also completed by a linear guide. In the rolling process of LCW-0QJ air molding machine, the cylinder is pneumatically pressurized, and the two pressure rollers are boosted on the forming drum, and the motor drives the left and right screws through the chain to separate the two pressure rollers. When rolling to the desired position, the contact block hits the stroke switch, the cylinder is vented, the pressure roller is lowered, the motor is reversed, and the two pressure rollers are merged into the pre-rolling position by the left and right screws. This can avoid leakage pressure at the center and ensure the quality of the molding. The pressing speed of the pressing roller of the electric device is not affected by the change of the diameter of the forming drum, the rolling time is fixed, and the rolling process has no leakage phenomenon, which improves the pressing quality of the green tire. The working speed of the rolling and the return speed of the empty car can also be set by variable frequency speed regulation, which is applicable to different specifications and process forming requirements. According to the needs of the product, in order to ensure the manufacturing precision, easy transportation, installation, commissioning, production and maintenance, as well as the adjustment and migration requirements of the enterprise development equipment, the whole machine base is set up, and the main machine box, the lower press roller and the tailstock assembly device are installed. On the base. Electrical and pneumatic installations are also mostly routed inside the frame, neat and beautiful, safe and intuitive. The air spring forming head structure is similar to the first radial tire forming head. According to the requirements of air spring forming, the outer tile curve is divided into several size tiles. When it is opened, it conforms to the forming curve. When superimposed, the diameter of the circumscribed circle is smaller than the diameter of the steel ring, and the blank can be withdrawn. The forming head and the mandrel are made into one assembly, and the replacement specification is very convenient and quick. The tire building head has a cylindrical forming head and a tapered forming head. The diameter of the steel ring on both sides of the forming head can be the same or different. When the different diameter is formed, the air spring forming head is tapered.

2022 02/15

- The Present Situation and Development Trend of Automobile Rubber Air Spring in ChinaThe rapid development of China`s auto industry over the past 10 years has resulted in a significant increase in technical content, manufacturing level, and output. However, looking at the overall strength of the entire Chinese auto industry, we are also very clear that there is still a big gap with the developed countries. Compared with us, we are still affected by the production technology of the entire vehicle. It is not possible to universally equip rubber air springs in cars, buses and trucks. The rubber air spring of automobile uses the elasticity and air pressure of the rubber to obtain the functions of comprehensive shock absorption, shock absorption, vibration isolation, noise prevention and buffering, thus playing the role of elastic support bearing the load. Rubber air springs are the core components of automobile shock absorption. Its performance directly affects the comfort of the automobile and the damage to the road. The current domestic situation is affected by the lack of independent intellectual property rights, imported models and bodywork of China's auto industry. China's rubber air springs have a certain gap between the production technology, product performance, quality and market share, and the development of the world auto industry. Stayed at the level of the 90s of the last century, especially in the supporting of large luxury passenger cars and large-scale trucks, there is still a big gap compared with foreign developed countries. At present, China's rubber air springs are mainly focused on the matching and application of railway trains and paper machines. Rubber air springs used in automobiles (especially for luxury passengers and trucks) started late in the country. According to the survey, the current domestic enterprises capable of large-scale production of automotive rubber air springs are the Guizhou Advance Rubber Factory and the Northwest Rubber Factory, and the Shaanxi Chenguang Rubber Factory is currently under research and development. Although there are air spring manufacturers in China, their product types are relatively single (mainly include long pillow type, curved bag type and membrane type), and the applicable size range is narrow (spring travel about 12 cm), and the product quality is Imported products are relatively poor (life of about 3 million times). Therefore, the scope of application of their products can only stay in the middle and low-end cars, and the added value is relatively low. The foreign automobile industry is relatively more developed than China, and therefore the supporting production technologies for its equipment and components are more advanced than those in China. In Europe and the United States and other developed countries, the penetration rate of air springs in cars has reached more than 95%; even in the passenger cars and trucks, the popularity of rubber air springs, they are at least 5-8 years earlier than our country. In foreign countries, rubber air spring production technology is more advanced than the German CONTITCH air spring manufacturing plant and the United States FIRESTONE air spring manufacturing plant. Their products are not limited to product types (membrane type, gourd type, bladder type, long pillow type), performance (steady body, comfortable ride, shockproof, noise-proof function), and applicable range (wide load range). It is still superior to domestic products in terms of quality (life of more than 3 million times), and it is particularly important that they have international technical standards and have great advantages in intellectual property rights. At present, domestic air springs have not been widely promoted due to various reasons. According to statistics, in 2002, the output of passenger cars for large and medium-sized passenger cars in China was 81,900, and the output of large and medium-sized passenger cars was 416,400. According to the equipment requirements, large buses and trucks each need at least 6 or 12 sets of air springs, and medium buses and trucks each need 4 vehicles. According to the above 50% of vehicle production, equipped with air springs and with 8 sets of equipment per vehicle, there are nearly 4 million sets of markets in the country; each set of air springs has a market price of about 8 billion yuan at the domestic minimum price of 2,000 yuan; In addition, plus air spring maintenance market (according to statistics, maintenance market is about one-fifth of the supporting market), the country has a market of nearly 10 billion yuan each year. Market research, in these markets, although there are a few domestic (such as Guizhou Advance Rubber Factory and Northwest Rubber Factory) manufacturers in the production, but by the vehicle technology, their products are limited to the maintenance market, and because of their relative products Single, the quality can not be compared with imported products, so it can only occupy a place in the low-end product market; in the high-end market still have to rely on imports (every year needs to spend billions of dollars on the **), imported products are almost occupied More than 80% of the high-end car accessories and maintenance market. Development trend Rubber air springs are an inevitable trend in the development and matching of today's automotive equipment, especially in large passenger cars and trucks. Conventional trucks generally use leaf springs or oil-and-gas springs as damping components. However, as the world's automobile industry is developing in the direction of high speed, high performance, comfort, safety, reliability, and easy maintenance, steel plates and oil-air springs are increasingly Not adapted to its development. For example, in Europe, the penetration rate of rubber air springs has basically reached 70-80%, and China is in the early stages of development. It is expected that in the next 10 years, rubber air springs will be equipped in a large number of vehicles, and the penetration rate will reach European modern times. Level. Rubber air springs are widely used in the automotive industry in China. The annual automobile production in China is about 3.25 million vehicles. The output of large and medium-sized buses and trucks is less than 1/6 of the total output. Passenger cars, light buses and trucks account for 2.75 million vehicles per year, especially on the air springs of cars. The development space is even greater. If China's auto production is increased year by year, its development market will be even wider. With the continuous improvement and development of China`s auto industry, the introduction of new models and bodies, the improvement of China`s highway construction level and mileage, and the introduction of road protection laws and regulations, as well as the use of coaches and trucks for long-distance transportation are comfortable. With the improvement of performance, China's rubber air springs will surely welcome spring from the main development. In view of the development direction of the world's auto industry production technology, the development direction of the production technology of rubber air springs will also be synchronized with it-the direction of strong shock absorption performance, long service life, and safety and reliability. This development trend has also clearly demonstrated that the research and application of rubber air springs in the formulation of new materials and its technology must inevitably go beyond the tradition, implement innovations, and implement independent intellectual property rights. Summary Recently, the National Development and Reform Commission has proposed a package of construction plans to improve the international level of China's auto industry in accordance with the current status of China's auto industry, and actively supported and guided the development of industry innovation systems and the development of independent intellectual property rights. In the field of rubber air springs, the entities that are given priority in development will surely obtain certain opportunities for participating in market competition, and they will also receive substantial returns in the market.

2022 02/07

- Analysis of the practice of using air spring /air strut /air shock system in trainsAmong the various professional companies affiliated to the group, there are companies specializing in the production of various types of air springs. The application of the products covers the following three aspects: (1) suspension of automobiles; (2) suspension of railways and rail vehicles; (3) industrial machinery Vibration isolation. ContiTech was the first company in Europe to develop air springs. In 1955, it began developing air springs for the automotive industry. For over 40 years, its products and technologies have grown rapidly. The following is a list of the development of air spring systems for railway vehicles: in 1956, an air spring for the German railway vehicle VT98 was developed; in 1962, a free diaphragm air spring for a bolsterless bogie was developed; 1968 In the year, a cylindrical air spring for the ET-420 vehicle was developed; in 1985, the first air spring for the NEICO pendulum body was developed; in 1988, the lateral stiffness was very low and the lateral stability was developed. Air spring system; in 1990, developed analytical software for railway vehicle air spring suspension systems; in 1993, developed air springs for high internal pressure; in 1994, developed air spring system for ICE-2 In 1995, an air spring system with high stationarity was developed; in 1997, an air spring for a suspension of bogies was developed; in 2000, an integrated circuit height for an air spring system was developed. At present, the daily output of ContiTech air springs is more than 11,000 sets, with 3.75 million sets in the whole year. The market share in Germany is the first in Germany, the first in Europe (60%), and the first in the world (accounting for 35%). The product is applied to almost all countries and regions that use air springs except Japan. ContiTech's air spring system has a global leading position because of its high technical level, good quality and complete specifications, which can meet various requirements and competitive prices. They value the development of new technologies and new products, investing 5% to 6% of sales expenses each year for research and development, and collaborating with universities, research institutions and other departments. The test equipment of the ContiTech air spring system is also leading the world. Application on railway vehicles ContiTech air spring systems are widely used in high-speed trains, tilting trains, fast trains and urban rail transit vehicles. Due to space limitations, only the first two will be introduced below. Applications on high-speed trains There are 320 to 330 high-speed trains around the world that use ContiTech's air spring systems, the most famous of which are the TGV series and the ICE series. In order to eliminate the high-frequency vibration of 10Hz transmitted by the round spring and improve its smoothness, the TGV-PSE adopted the 684N4.10B air spring with high flexibility in the vertical and horizontal directions manufactured by ContiTech in the early 1980s. The 168L large-capacity additional air chamber is used to reduce the vertical and lateral natural vibration frequencies of the vehicle body to 0.7Hz and 0.75Hz respectively. The test results of the two spring devices are as follows: (1) Vertical vibration acceleration: vertical stability The sex index (fatigue time) is: spiral spring 12h, air spring 24h. (2) Lateral vibration acceleration: The lateral stability index (fatigue time) is: spiral steel spring 10h, air spring 15h. That is, the vertical and horizontal stability indexes are increased by 1 time and 0.5 times, respectively. Accordingly, this type of spring is widely used on all TGV-PSE trains. This highly flexible air spring arrangement ensures that the TGV still has excellent running stability when it created the world record 515.3km/h in 1990. Later, the French National Railways SNCF accepted the recommendation of ContiTech. Since 1992, all the air springs of the TGV-PSE trains have been connected in series with a 100.260 cone rubber pile. The advantage is: prolonging the life of the air spring;

2022 01/18

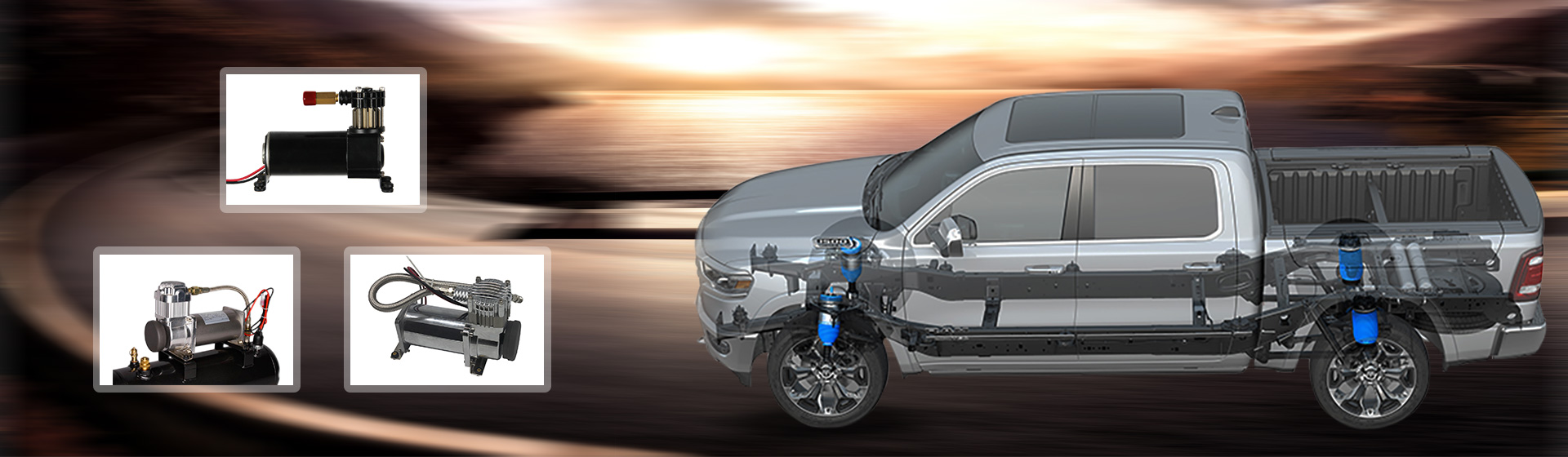

- AAPEX (Air suspension compressor )Automotive Aftermarket Products Expo (AAPEX) has been the premier global event representing the $1 trillion global aftermarket auto parts industry. Located at the Sands Expo, AAPEX 2019 will feature over 2,500 automotive aftermarket manufacturers and suppliers showcasing innovative products, services and technologies to over 51,000+ targeted buyers. AAPEX is co-owned by the Auto Care Association and the Automotive Aftermarket Suppliers Association (AASA), the light vehicle aftermarket division of the Motor & Equipment Manufacturers Association (MEMA). HANGZHOU WANRAY INDUSTRY Booth number:8411 November 5-7, 2019 Las Vegas, NV Sands Expo

2019 10/15

- The Dubai Automechanika FairAs the largest international automotive aftermarket trade show in the Middle East, Automechanika Dubai acts as the central trading link for markets that are difficult to reach connecting the wider Middle East, Africa, Asia and key CIS countries. Be part of the 18th edition to find out more about the latest products and services, find new suppliers, source products and compare product alternatives. Date: 7 – 9 June 2020 Time: 10 AM to 7 PM Venue: Dubai World Trade Centre, UAE Wanray attended this big Fair. This is the photo of the booth. We are the 10 years' trustable manufacturer on air suspension compressors.

2019 06/19

- China has so far issued 109 licenses for autonomous vehicle road tests by AprilShanghai (Gasgoo)- By the end of April this year, there were a total of 109 licenses that have been issued to companies across China for their autonomous driving road tests, according to a summary done by AutoInfo, a Chinese automotive information website. So far, 16 cities have got their enterprises received the licenses, among which Beijing owns the most-up to 59 pieces. The runner-up Chongqing, issuing 12 licenses in total, has attracted a number of applicants with its abundant geomorphic resources. Jiangsu Province released a total of 7 licenses-2 pieces for Wuxi, 3 pieces for Changzhou and 2 pieces for Suzhou. Part of cities inclined to dispatch more licenses to commercial vehicles (CVs), such as Changsha, Pingtan, Jinan, Changzhou, Baoding and Xiangyang. Some testing areas are specifically chosen for CV makers and technology developers to conduct tests. Up until now, a total of 17 CV-used licenses have been issued to enterprises. Although the percentage is still quite small, autonomous driving R&D over CVs is gaining increasingly more and stronger supports in infrastructures and policies. From the time being, 35 companies in total were given the licenses. Baidu possessed nearly 50% of total pieces with its footprints scattering in 5 cities including Beijing (45 pieces), Pingtan (3 pieces), Chongqing (1 piece), Changsha (1 piece) and Tianjin (1 piece). Technology companies also present a great zeal in road testing self-driving vehicles. Pony.ai, a Guangzhou-based autonomous driving startup, has received 5 licenses, closely following Baidu in terms of license numbers.

2019 05/16

- Trump plans to delay auto tariffs amid EU, Japan trade talksWASHINGTON -- President Donald Trump is poised to delay a decision by up to six months to impose auto tariffs to avoid blowing up negotiations with the EU and Japan and further antagonize allies as he ramps up his trade war with China, according to people close to the discussions. Trump faces a May 18 deadline over how to proceed with his threat to slap a tariff of as much as 25 percent on imported cars and parts in the name of U.S. national security. The news was welcomed by an equities market that has been battered by renewed trade concerns since last week. General Motors deferred comment on the tariff decision delay to industry representatives, while Ford Motor Co. declined to comment and Fiat Chrysler couldn`t be immediately reached. Trump, who is due to make a state visit to Japan later this month, remains the wild card, according to people close to the discussion. Trump and a small group of aides including Commerce Secretary Wilbur Ross and trade adviser Peter Navarro are seen to be in favor of the new import duties against the advice of other advisers. Tariff delay But people close to the discussions say even advocates of tariffs are still debating the scope of any action, complicating the discussions. Other advisers including U.S. Trade Representative Robert Lighthizer, who is leading the negotiations with the EU and Japan, have been urging Trump to postpone a decision, according to administration officials and other people familiar with the deliberations. CONTENT FROM IHS MARKIT European connected car review extended by two months A review of the standard that will be used to connect vehicles with other vehicles and the surrounding environment in Europe is set to be extended by two months, reports Reuters. READ MORE At a White House meeting on Tuesday, officials firmed up the decision to delay tariffs for up to 180 days, according to two people familiar with the deliberations. A decision is expected to be announced publicly before the end of the week. Spokespeople for Ross and Lighthizer did not immediately respond to a request for comment, and the White House declined to comment. Trump last year ordered a Commerce Department investigation into whether imported cars and parts posed a threat to U.S. national security and he was presented with a final report laying out a series of recommendations in February. The findings weren`t publicly released. According to people who have seen the report, the justification for auto tariffs is not that the imports of vehicles and auto parts per se are a threat to national security, but it`s the portion they contribute to the overall U.S. trade deficit that could cause harm. [The reason autos are very important to our trade picture is about half of our trade deficit comes from the single product, automotive, and about the other half of our trade deficit comes from a geographic area and that`s called China," Ross said on Friday. In closed-door meetings with foreign countries and auto representatives, officials from the U.S. Trade Representative`s office and Commerce have indicated for several weeks that the president will delay his decision and the duties will not derail ongoing trade negotiations. Trump advisers have cautioned the president that action on auto tariffs could risk serious pushback from Congress. Trump`s own party is threatening to move forward with legislation to limit the president`s tariff authority with many in Congress saying duties on cars, which are widely opposed by the auto industry, would be a step too far. USMCA agreement Trump`s advisers for months have been debating a strategy to delay the deadline and make the case that imposing broad auto tariffs would derail not only trade talks with Japan and the EU but also passage of the new U.S. Mexico Canada Agreement through Congress. Auto industry representatives have been working closely with USTR and the White House to publicly tout the benefits of USMCA and supported a White House study last month that laid out the expected job increases if the deal gets approved by Congress and fully implemented. After the Trump administration faced massive resistance from auto companies during the negotiations for the new NAFTA, they are now among the biggest proponents of the deal. The U.S. imported $191.7 billion in passenger vehicles and light trucks in 2018 with more than $90 billion of those imports coming from Canada and Mexico, which are duty-free under NAFTA. Passenger cars are now subject to a 2.5 percent U.S. tariff but Trump has threatened to raise that to 25 percent, arguing that the EU and other countries have higher barriers to U.S. auto exports. Any new tariffs would hit imported cars from Japan, South Korea and Europe hardest. But they would also hit the supply chains of many domestic producers who rely on imported parts and foreign automakers with manufacturing operations in the U.S. Tariffs on European cars imported into the U.S. would disproportionately hurt Volkswagen Group's Porsche and Audi brands, as Porsche imports all of its U.S.-sold cars from Europe, while Audi imports more than two thirds, according to data compiled by Bloomberg Intelligence. Mercedes-parent Daimler AG would also be affected, as 64 percent of its U.S.-sold cars come from Europe. BMW AG would be slightly better off, with more than half of its U.S. cars being made locally. The National Automobile Dealers Association estimates that the tariffs would add as much as $2,270 to the cost of U.S.-built cars and $6,875 to the cost of imported cars and trucks. [We are deeply concerned that the administration continues to consider imposing auto tariffs," the Alliance of Automobile Manufacturers, a trade group representing the largest domestic and foreign car makers with operations in the U.S., said in a statement. [At the end of the day, you can have tariffs or investment, but you can`t have both."

2019 05/16

- GM's Engle touts pickups' transaction price gainsGeneral Motors is losing market share in the light-duty pickup segment this year, but it's hauling in thousands of dollars more on average for each model. GM, citing J.D. Power PIN data, reports average transaction prices for the 2019 GMC Sierra are up $4,300 from a year earlier to $48,500 through April. The 2019 Chevrolet Silverado is up $3,000 during the same period to $41,700. "Our market performance is exactly where I would expect it to be at this point in the launch with good results in the places where we've focused," said Barry Engle, GM president of the Americas, during a presentation Wednesday at the Goldman Sachs Industrials & Materials Conference in New York City. The Sierra, according to GM, leads the full-size pickup segment in average transaction price, while Silverado trails Ford F series, up $300 to $43,000. Fiat Chrysler Automobiles' Ram pickup has increased $3,700 - the second most behind Sierra - but its average transaction price remains below its American competitors and Toyota, at $39,700. 'Crown jewel' Sustaining such high transaction prices could be challenging as GM continues to move away from the initial launch of its redesigned full-size pickups, which began last fall. Likely assisting in the pricing power will be the introduction of a new inline-six diesel engine for the light-duty models in the coming months and the introduction of GM's redesigned heavy-duty models. Also assisting the pricing is GM's decision to increase capacity of more profitable crew cab models with the redesigned pickups. Production of the Sierra and Silverado HDs is expected to begin in June, according to Engle.

2019 05/16

- BYD delivers 15 eBuses to Badajoz, SpainBYD has this week delivered 15 pure electric 12-metre eBuses to Spain's southwest city of Badajoz – one of the largest eBus orders for BYD in the country. Public transport operator, TUBASA (Transportes Urbanos de Badajoz, SA), part of Grupo Ruiz and one of Spain'sprincipal road passenger transport groups, has already put the vehicles into service. The zero emission BYD eBuses are delivered as fleet replacements for TUBASA and are already returning substantial savings when compared to the company'sprevious diesel-powered buses. 15 BYD eBuses delivery in Badajoz The BYD eBus delivery was marked at a special handover ceremony in Badajoz on Thursday 9th May including representatives from TUBASA and the Mayor of Badajoz, Franciso Javier Fragoso. The BYD fleet delivery means Badajoz becomes the largest user of electric buses in Spain, with TUBASA operating the highest percentage of electric buses within any public transport fleet in Europe. In a significant commitment to making the city even more environmentally friendly, the Mayor has pledged that the move to a 100% all-electric bus fleet will continue in Badajoz. Powered by BYD Iron-Phosphate batteries, the new BYD eBuses boast a 250km range between charges under SORT 2 conditions. Based at El Nevero industrial estate, TUBASA has installed 15 recharging points and 100% recharge is achieved in just four hours. [TUBASA has established a clear commitment to emission-free operation in Badajoz," said Mr. Javier Contijoch, V.P. Sales for BYD Europe, [and we are delighted that the company has chosen BYD as its eBus partner. We have demonstrated that pure electric operation will deliver significant cost savings for TUBASA, but, moreover, the benefits for passengers, other road users and the wider public will be realised for many years to come. From left to right] Mr. Julián Pocostales, Managing Director of TUBASA; Mr. Jesús Coslado, Councilor for Transports of Badajoz; and Mr. Javier Contijoch, VP Sales of BYD Europe BYD also confirmed an order for eight 12-metre eBuses for Badalona in Barcelona province, scheduled for delivery very soon, with further orders for bus operators in Madrid and Valencia. The Portuguese city of Coimbra is also gearing-up to receive a delivery of eight BYD eBuses next week, signaling the growing demand across the Iberian Peninsula for BYD'spure electric 100% emission-free eBus products. Isbrand Ho, Managing Director at BYD Europe: [Our potential in the Iberian market is rapidly growing with consecutive orders from Spain and Portugal. Up till now we have confirmed 32 eBuses that will be running in both countries by summer 2019, and we have confidence there will be more to come. We are pleased that these cities have already chosen for zero emission buses that contribute to the air quality."

2019 05/16

- 2019 Auto Shanghai Fair

2019 05/05

- Auto Shanghai 2019: Cloudy with a chance of sunshineAuto Shanghai 2019, or the 18th Shanghai International Automobile Industry Exhibition, is just around the corner. The biennial show that falls on each odd year, like its [sibling" show Auto China in Beijing on even years, is by far the largest in the world no matter how you measure it. According to show organizers, more than 1,000 companies from 20 countries and regions are expected to exhibit on over 360,000 square meters of floor space filling up all 12 halls at the National Exhibition & Convention Center in Shanghai. Expect hundreds of global debuts, thousands of cars and SUVs to be displayed and more than a million visitors to come to the show, if the previous edition in 2017 is any indication -- 1.01 million visitors came that year. It will also be the most dizzying show, thanks to the sheer size of the venue and its flower-shaped layout. And yes, all the halls have two floors of exhibition space. Prepare to be dazed and confused. Even after all these years of attending the show, I still haven't figured out my way around. The decline of total vehicles sales happens to be the current state of the Chinese auto industry as well: automakers are trying to navigate their way around a major "hiccup" never seen in its history. Traffic flow at night in Beijing. /VCG Photo Auto sales have fallen for nine consecutive months (March sales fell 5.18 percent, while Q1 sales saw a year-on-year decrease of 11.32 percent) since last July, as annual sales in 2018 fell for the first time in 28 years. They could fall again 2019, according to some estimates. Auto Shanghai 2019, therefore, will kick off under this major backdrop overshadowing the largest industry party of the year. But the sales slowdown is not the only backdrop adding uncertainty into the market. As the country has just announced a huge cut on new energy vehicle subsidies for 2019, rumors and discussions on what foreign automakers might do as far as raising their stakes in vehicle joint ventures is concerned (BMW has already done it and Volkswagen is rumored to take majority ownership of one of its JVs) are picking up steam now that the 50:50 equity requirement has been lifted, and pressure is mounting on automakers to meet the tough corporate average fuel consumption targets and NEV credit policy that will go into effect this year requiring NEVs to generate enough points as a certain percentage of vehicles sold. The good news is, a major [rescue" measure, announced right before the Chinese New Year, as well as the recent reduction of manufacturing VAT tax from 16 to 13 percent, which has resulted in a [price war," are in place to boost consumption. Auto Shanghai 2019 will thus be held during the most complex market environment in recent memory. The party, however, must go on. What's being served up? The show will pit the traditional foreign automakers, traditional Chinese automakers and the Chinese smart EV startups, what I call the [three forces," against each other more than ever. Volkswagen's I.D., an autonomous self-driving concept vehicle, is displayed at the Consumer Electronics Show 2017 in Las Vegas, Nevada, U.S., January 5, 2017. /VCG Photo So there are at least three things to look forward to at Auto Shanghai 2019. First, foreign automakers will finally bring their NEV offensive to the show with the debut of numerous locally-produced NEV models, especially from big brands like Volkswagen. Remember, China's NEV market up until now has been dominated by the traditional Chinese brands. In addition, the Chinese traditional automakers will take it up a notch with debut of more futuristic concepts and upper-scale production models, including quite a few [Tesla killers." Those that are at the front of the pack like Geely, Great Wall and BYD will widen the gap with second-tier brands and the also-rans in terms of styling and build quality that will even outshine the established foreign counterparts. Moreover, Chinese smart EV startups are rushing to debut their second or even third vehicles in concept form, despite the fact that some of them haven't even launched their first vehicle to market yet. Then we shouldn't forget the tier-1 suppliers. Close to half of the top 100 global tier-1 suppliers are expected to exhibit, taking up top floors of two halls. Many of these suppliers, who nowadays like to call themselves technology companies, have their China or Asia Pacific headquarters based in Shanghai so it's basically home court advantage, hence the turnout (relative to Beijing). Quite a few suppliers will have their global CEOs on hand to personally talk about China's new role in terms of developing technologies here for global applications, rather than the other way as used to be the case. They are also banking on content growth despite the volume slowdown, as vehicles get smarter and more electrified. Last but not least, look for the smaller Chinese startups in the autonomous driving tech space in a special [future mobility" exhibition zone in Hall 3H. It will be like a mini CES. Chinese automaker Geely unveils the first model of its new Lynk & Co brand in Berlin, Germany, October 20, 2016. /VCG Photo As has been the case in recent years, to avoid the noise on press days, many of the [three forces" will be holding their brand nights a day, or two, or three in advance of the first press day on April 16. Heck, Ford debuted its all-new Escape at an event on April 3, almost two weeks earlier. Half of the show will be over by the first press day and most of it will be over by noon that day (there will be a total of 136 press conferences on April 16-17), at least from a media perspective, as automakers jostle for headlines. Crazy party in crazy times. Auto Shanghai 2019 at least provides automakers a break from the uncertainty blanketing the industry, with the expectation that the market in the second half of the year will rebound. Sunshine seems to be peering through the cloud. Will the weather turn sunny or more rainy? I guess that will depend on the effectiveness of the stimulus policies and automaker's ability to entice Chinese consumers to buy. What will be certain is that competition will only get fiercer and winners and losers decided faster, which is a good thing for the industry.

2019 05/05

- 2019 Auto Shanghai

2019 05/05

- When you see the new BMW X5, you're ready to driveThe new generation BMW X5, which has just come out, will start with just two 40i models, both with M sports suits.Although the configuration did not give people too many surprises, but the performance of the new generation of vehicles in the driving, I was pleased.On the day of the launch, tachehui has made a detailed description of the exterior and interior decoration of the new generation X5. Today, we will mainly talk about the driving performance. The front seat has a very rich regulation function, in addition to the conventional front and rear, backrest, leg support and waist support, but also supports the manual regulation of headrest cushion, the electric regulation of the upper part of the seat and the electric regulation of the tightening of the two wings. Since there are many adjustment functions, when you adjust the seat, the central control screen will display the function indicator of the button you touch in real time, which can effectively prevent misoperation.In addition, there are heating, ventilation and three levels of massage function, and support heating and ventilation function at the same time. Due to the lack of time, I did not experience the seat in the back seat, but there is no USB interface in the back seat, which is only equipped with 12V power supply. If the back seat is made in China in the future, whether it changes or not will determine the advantage of X5. Before the X5 test drive, I happened to experience BMW's 750Li and M5 F90 models successively. The sound insulation effect of several cars is better than one another, which makes flagship brother 7 series appear a little embarrassed.Even with the extra large 21-inch wheel rim, the only noise source on the road is extremely fine wind noise.But on the gravel road, you can still feel the rim size of your car. Before the X5 test drive, I happened to experience BMW's 750Li and M5 F90 models successively. The sound insulation effect of several cars is better than one another, which makes flagship brother 7 series appear a little embarrassed.Even with the extra large 21-inch wheel rim, the only noise source on the road is extremely fine wind noise.But on the gravel road, you can still feel the rim size of your car.

2018 12/10

- 2018 Shanghai Frankfurt auto parts exhibition concluded successfullyFrom November 28th to December 1st, 2018 Shanghai Frankfurt Auto Show was on schedule, and thousands of auto parts manufacturers and suppliers gathered here. Hangzhou Wanrui Industrial (Hangzhou Haorui Industrial Co., Ltd.) is located at the 36 square meter booth of 4.1 D18. The exhibitions are all series of air compressors developed by our company in Hangzhou Wanrui. The products cover European cars (Land Rover, Mercedes-Benz, BMW, Audi, etc.), American cars (Cadillac, Lincoln, etc.), modified cars and other models. The product range is complete, providing customers with more choices. We also placed a fish tank in the booth, and an air compressor was placed inside the fish tank to work continuously to show the waterproofness and stability of our products and our confidence in our products. The Wanrui booth with complete categories and design atmosphere has once become the focus of foreign businessmen. From November 28th to December 1st, the four-day exhibition, with the unremitting efforts of all members of our company, won the favor of more than 300 customers. All the employees of the exhibition actively promoted their suggestions and suggestions, and all departments worked together to demonstrate the good teamwork spirit of Hangzhou Wanrui Industry. Congratulations on the success of Wanrui Industrial in Shanghai 2018 Shanghai Auto Show!

2018 12/05

Email to this supplier